Tools of Discovery: How new equipment is powering research breakthroughs at Penn State

By Jamie Oberdick

From growing perfect crystals to testing materials in real-world conditions, Penn State’s advanced lab tools are making scientific breakthroughs possible

Great ideas and brilliant researchers are essential for discovery—but so is having the right equipment. At Penn State, scientists are pushing the boundaries of materials science thanks to new, state-of-the-art tools that let them explore questions they couldn’t answer before.

Take crystal growth, for example. Zhiqiang Mao, professor of physics, materials science and engineering, and chemistry, leads research using a unique tool called the double-crucible vertical Bridgman (DCVB) furnace. It’s the first of its kind in the world and allows scientists to grow large, ultra-pure crystals. This is something critical for creating better electronics, sensors, and communication devices.

“Large single crystals with just the right composition are the foundation for many technologies,” Mao said. “They’re also essential for understanding the basic science behind materials.”

Unlike traditional methods, this new furnace avoids common problems like impurities and uneven layers. That means researchers can make better materials for everything from cell phones to solar panels.

Another game-changing area is a technique called in situ testing. It means researchers can watch how materials behave while they’re being exposed to things like heat, pressure, or gas. This is similar to what they’d experience in real life.

“In situ testing gives us a window into how materials change and perform,” said Jordan Meyet, who leads in situ capabilities at the Materials Characterization Lab (MCL). “Instead of guessing, we can see exactly what’s happening.”

For example, if a scientist is developing a new sensor for detecting carbon monoxide, they need to know how the material reacts to that specific gas, not just to air in general. “You have to expose the sensor to the actual gas it’s supposed to detect,” Meyet said. “That’s how you find out what really works.”

To make this possible, Penn State built a custom gas system that delivers exactly the right environment for experiments. It’s safe, precise, and permanent; meaning researchers don’t have to rebuild it every time. That makes experiments easier to repeat and the results more trustworthy.

“Reproducibility is key,” Meyet said. “When everything stays the same, you know the results come from the material, and not from a setup error. It also helps us teach others how to do this kind of research the right way.”

Josh Stapleton, associate research professor and the director of the MCL at the Materials Research Institute, says that’s part of the broader mission. “The researchers who know they need these tools are already using them,” he said. “But there are many more who could benefit if they knew what’s available. We want to spread the word.”

MRI is also pioneering new ways to make two-dimensional (2D) materials, which are just one or a few atoms thick. These materials are key to building future technologies like advanced computing and flexible electronics.

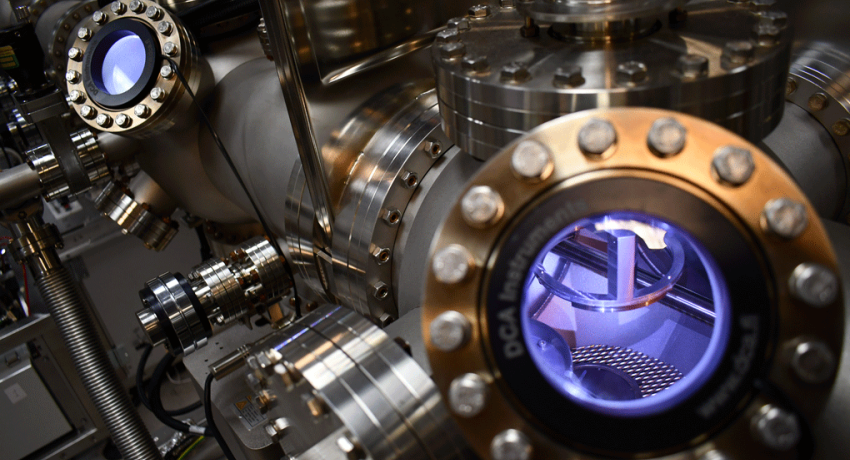

Josh Robinson, professor of materials science and engineering and director of the onsemi Silicon Carbide Crystal Center (SCIA) at Penn State, oversees a tool called the confinement heteroepitaxy (or CHet) system. It’s located in the Materials Research Institute as part of the 2D Crystal Consortium Materials Innovation Platform, and lets researchers grow 2D forms of traditionally 3D materials at the wafer scale. That’s a big step toward using these materials in real-world electronics.

“We’re growing 2D materials directly on wafers used in the semiconductor industry,” Robinson said. “That opens the door for future applications like brain-inspired computing or next-gen quantum devices.”

Each of these tools, from crystal growth to gas testing to 2D material synthesis, is more than a piece of equipment. It’s a gateway to new research, new partnerships, and new possibilities. These tools attract collaborators from across the country and around the world, including industry partners eager to prototype and test new ideas.

“Penn State isn’t just supporting today’s research,” Stapleton said. “We’re building the tools and infrastructure that will shape science and technology five or ten years down the road.”

As new equipment comes online and more researchers use it, Penn State is helping transform big ideas into real-world impact, one experiment at a time.

For a deeper dive into our core facilities at MRI, watch our video and subscribe to our YouTube Channel

N-315 Millennium Science Complex University Park, PA 16802